- Clean Technology Manufacturing presents a promising solution for mitigating the environmental impact of the manufacturing sector.

- Embracing cloud technology is proving to be a game-changer, empowering enterprises to reach their net zero objectives.

- Unified Data Management Platform (UDMP) is a vital catalyst to this transformation.

As the world grapples with ever-growing environmental challenges, the need for sustainable practices in industries has become more critical than ever. Clean Technology Manufacturing, also known as Green Manufacturing, offers a promising solution to reduce the environmental impact of the manufacturing sector. In this blog, we will explore the concept of clean technology manufacturing, its impact on emissions, and howcloud technology acts as a key enabler in driving sustainability.

What is Clean Technology Manufacturing?

The United Nations has long been at the forefront of global sustainability efforts. The organization has consistently championed the cause of combating climate change and promoting environmental stewardship. Through initiatives like the Sustainable Development Goals (SDGs) and the Paris Agreement, the United Nations urges industries, including manufacturing, to take decisive actions to reduce their carbon footprint.

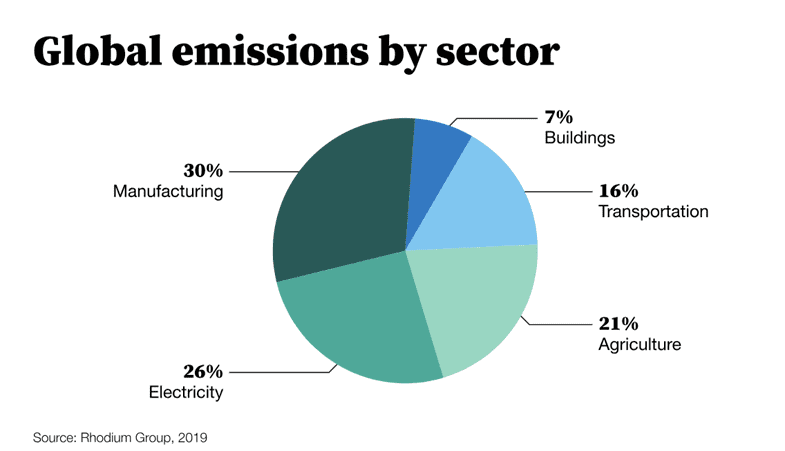

The manufacturing industry itself has been increasingly proactive in addressing its environmental impact. According to a report by the Global Manufacturing and Industrialisation Summit (GMIS), the manufacturing sector is responsible for approximately 20% of global greenhouse gas emissions. As a result, many manufacturing companies are adopting clean technology practices to reduce emissions and align with international sustainability goals. That brings us to the question: What is Clean Technology Manufacturing?

Clean Technology Manufacturing involves adopting eco-friendly processes, technologies, and materials to minimize the environmental footprint of industrial production. The primary goal is to reduce greenhouse gas emissions, promote resource efficiency, and ensure responsible waste management throughout product lifecycle management.

Real-World Examples of Clean Technology Manufacturing in Action

Clean technology manufacturing is an exciting and transformative approach to making industries more sustainable and environmentally friendly. Let’s dive deeper into some real-world examples and how these practices are making a difference.

- Renewable Energy Adoption: Renewable energy sources, like solar and wind power, are game-changers in the manufacturing world. They not only help reduce greenhouse gas emissions but also offer a more stable and long-term energy solution. Take IKEA, for instance. This global furniture giant has committed to investing €4 billion in renewable energy projects, including solar installations in its stores and factories. These solar panels are estimated to generate approximately 700 gigawatt-hours of clean electricity annually. These solar installations generate clean electricity, reducing IKEA’s reliance on fossil fuels and significantly cutting down its carbon footprint.

- Energy Efficiency Measures: Improving energy efficiency is another crucial aspect of clean technology manufacturing. Companies, big and small, are actively seeking ways to optimize their energy usage and minimize waste. One notable example is Toyota, a pioneer in the automotive industry. Through advanced manufacturing practices, Toyota has revolutionized the way cars are produced. Toyota’s adoption of lean manufacturing and energy-efficient technologies has led to an impressive 40% reduction in energy consumption per vehicle produced. By streamlining processes, reducing energy-intensive steps, and eliminating unnecessary waste, Toyota has achieved remarkable energy savings. Not only does this help the environment, but it also leads to cost savings, making it a win-win situation.

- Circular Economy Approach: Embracing the circular economy is a fantastic strategy to tackle waste generation and promote sustainability. One company that stands out for its circular approach is Patagonia, the outdoor clothing company. Patagonia encourages its customers to return used garments for recycling and repurposing. Instead of ending up in landfills, these garments get a new lease on life as they are transformed into new products or materials. This closed-loop system minimizes waste and conserves resources, making Patagonia a shining example of how clean technology manufacturing aligns with a circular economy vision.

It’s remarkable to witness how clean technology manufacturing is reshaping industries across the globe. By combining renewable energy sources, energy efficiency measures, and a circular economy mindset, companies are taking significant steps toward a greener future. And what’s truly amazing is how the cloud is stepping up to the plate and becoming a game-changer for clean technology manufacturing. It’s like the perfect match made in eco-heaven! Let’s take a closer look at how the cloud is making all the difference.

Unleashing the Power of Cloud Computing in Clean Technology Manufacturing!

Did you know that moving backend operations to the cloud is like opening the floodgates of data in the best possible way? Manufacturers are diving into a world of possibilities where they can now collect and analyze mind-boggling amounts of real-time environmental data. It’s like having an eco-superpower at their fingertips! With the cloud’s capabilities, manufacturers can gather data on energy consumption, emissions, waste management, and more. And brace yourself for this – renewable energy sources like solar and wind are booming, accounting for a staggering 26% of the world’s electricity generation! (International Energy Agency)

Picture this: Manufacturers now have a crystal ball to see the impact of their actions on the environment and adjust their strategies accordingly. With all this data firepower, companies can make informed decisions to boost sustainability practices and reduce their carbon footprints. It’s like having a real-time eco-dashboard guiding them toward a greener future! And that’s not all! Thanks to cloud-based systems, manufacturers can now embrace some serious remote monitoring wizardry. Imagine keeping an eagle eye on critical environmental metrics like energy usage, emissions, and more, all in real-time, from anywhere in the world. It’s like having a cosmic eco-control center while casually sipping your morning coffee!

By proactively managing and optimizing operations through remote monitoring, manufacturers can spot areas that need improvement and swiftly act to be more environmentally friendly. The impact? Impressive energy savings of up to 50% have been achieved through energy efficiency measures! (U.S. Department of Energy)

Now, here’s where it gets even more exciting. Some of the major cloud service providers are taking sustainability to the next level by pledging to reduce their carbon footprint. Let’s talk about Amazon Web Services (AWS) – they’re on a mission to achieve net-zero carbon emissions by 2040. And guess what? They’re not just paying lip service to this commitment. AWS has made substantial investments in renewable energy projects to power its data centers and infrastructure, with the goal of transitioning to 100% renewable energy. They have also launched the Climate Pledge Friendly program, encouraging customers to make sustainable choices by identifying and promoting environmentally responsible products. The Amazon Sustainability Data Initiative (ASDI) facilitates environmental research by providing researchers with access to cloud technology and large datasets. Furthermore, AWS continually focuses on improving the energy efficiency of its data centers and offsetting unavoidable emissions through carbon offset projects. As a co-founder of The Climate Pledge, AWS commits to meeting the Paris Agreement goals 10 years ahead of schedule by reporting and reducing greenhouse gas emissions and advocating for policy changes.

And, of course, we can’t forget about Microsoft Azure. They’re aiming to be carbon negative by 2030! That’s right – negative, as in they want to remove more carbon from the atmosphere than they produce. Now, that’s some serious dedication to sustainability! Microsoft aims to achieve this through a multi-faceted approach, including 100% renewable energy usage for its data centers, research and development of low-carbon technologies, and carbon offset projects to compensate for any remaining emissions. The company also focuses on sustainable data center designs and operations, energy efficiency improvements, and water conservation efforts. Additionally, Microsoft invests in ecosystem restoration projects and supports sustainable practices in its supply chain to reduce its carbon footprint further.

Clean technology manufacturing is a powerful and innovative approach that holds the potential to revolutionize industries for the better. By adopting renewable energy, optimizing energy efficiency, and embracing a circular economy mindset, companies are stepping up to tackle environmental challenges head-on. When combined with the cloud’s capabilities, these efforts become even more potent, facilitating data-driven decisions and sustainable practices on a global scale. As we witness more companies and industries embracing clean technology manufacturing, we can be hopeful for a future where environmental sustainability becomes the cornerstone of our way of life.

Embarking on the journey towards Clean Technology Manufacturing and achieving net zero goals is an exciting prospect for enterprises. However, before they soar to the cloud or do it while keeping their operations on-premise, there’s a vital step that must not be overlooked – A Unified Data Management Platform (UDMP). UDMP involves integrating and centralizing all the data generated and utilized across various departments and processes within a manufacturing company. It aims to streamline data access, storage, and analysis, creating a single source of truth. This invaluable resource enables better decision-making and improved efficiency and fosters collaboration among different teams. With UDMP in place, the manufacturing process becomes more seamless and effective, propelling enterprises closer to their net zero objectives. Let’s find out five ways how.

Accelerating the Path to Clean Technology Manufacturing: 5 Key Benefits of UDMP

- Comprehensive Data Analysis for Informed Decisions: A Unified Data Management Platform collects and integrates data from various sources within the manufacturing process, such as energy consumption, emissions, and waste management. By analyzing this comprehensive dataset, manufacturers gain valuable insights into their environmental impact and can make data-driven decisions. According to a study by McKinsey, data-driven decision-making can lead to a 5-6% reduction in greenhouse gas emissions, positively impacting sustainability efforts.

- Real-time Monitoring and Proactive Management: With real-time monitoring capabilities, manufacturers can keep a constant watch on critical environmental metrics. This proactive approach enables them to identify any deviations or inefficiencies and take immediate action quickly. Manufacturers can potentially reduce energy consumption by up to 20%, as reported by the US Department of Energy.

- Resource Optimization for Waste Reduction: A Unified Data Management Platform facilitates resource optimization, helping manufacturers identify areas where resource usage can be minimized. This includes optimizing raw materials, water consumption, and energy usage. A study by the World Economic Forum estimates that resource optimization strategies can result in cost savings of up to $900 billion by 2030.

- Predictive Maintenance for Equipment Efficiency: By leveraging advanced analytics, the platform enables predictive maintenance, anticipating potential equipment malfunctions or breakdowns. This ensures that manufacturing machinery operates at peak efficiency, reducing energy waste and increasing equipment longevity. A study by the US Department of Energy suggests that predictive maintenance can improve energy efficiency by up to 30%.

- Streamlined Compliance and Reporting: Clean technology manufacturing often involves adhering to specific sustainability regulations and reporting requirements. A Unified Data Management Platform simplifies compliance by automating data collection, organizing it according to regulatory standards, and generating accurate sustainability reports. This streamlines the reporting process, reducing the time and effort required for compliance activities.

The Data Dynamics Advantage

Data Dynamics is a leading provider of enterprise data management solutions, helping organizations structure their unstructured data with their Unified Unstructured Data Management Platform (UDMP). The platform encompasses four modules- Data Analytics, Mobility, Security, and Compliance. Proven in over 300 organizations, including 28 Fortune 100, the Platform uses a blend of automation, AI, ML, and blockchain technologies and scales to meet the requirements of global enterprise workloads. With Data Dynamics, enterprise customers can eliminate the use of individual point solutions with siloed data views. Instead, they can utilize a single software platform to structure their unstructured data, unlock data-driven insights, secure data, ensure compliance and governance, and drive cloud data management. Ultimately, the company’s vision is to help enterprises achieve data democratization so that users, no matter their technical background, can instantly access, understand, and derive maximum insights from unstructured data sprawls.

To learn more about Data Dynamics and its transformative capabilities, please visit www.datadynamicsinc.com or reach out to solutions@datdyn.com / (713)-491-4298.

Embrace the clean technology manufacturing revolution with Data Dynamics as your strategic ally!