Highlights:

- According to recent statistics, the number of connected IoT devices is expected to surpass 35 billion by 2025, with manufacturing being one of the top industries benefiting from this surge.

- The sheer volume of data generated by IoT devices can be overwhelming. Storing, managing, and processing this data requires robust infrastructure.

- Success in IoT isn’t merely about implementing smart devices and sensors across manufacturing facilities. The crux lies in effectively managing, curating, and utilizing the generated data.

- When it comes to pushing the envelope in IoT adoption, Microsoft Azure stands out. Azure’s comprehensive suite of IoT solutions empowers organizations to connect, monitor, and manage their IoT assets seamlessly.

In this Blog

Amid the digital revolution, the Internet of Things (IoT) concept has emerged as a transformative force, revolutionizing industries across the spectrum. With its profound impact on manufacturing, IoT has become the cornerstone of the Industry 4.0 movement. In this blog, we will delve into the evolution of IoT, the significance of IoT data, and how Microsoft Azure is at the forefront of driving its adoption, thereby reshaping the manufacturing landscape.

The Evolution of IoT: From Concept to Reality

Internet of Things (IoT) emerged as a visionary idea in the late 20th century, when interconnected devices seemed like something straight out of science fiction. The notion of everyday objects communicating with each other, sharing data, and collaborating to enhance our lives was a futuristic concept that captivated the imagination of innovators and thinkers. It was a tantalizing glimpse into a world where technology could transcend its conventional boundaries and weave itself into the fabric of our daily existence.

As time passed, this visionary concept gradually transformed into a tangible reality. The groundwork for IoT was laid with the development of the first networked devices that could communicate with each other. These early experiments and prototypes paved the way for an interconnected ecosystem of devices, sensors, and machinery.

Fast forward to today, and the vision of IoT has not only materialized but has transformed into a dynamic network that spans across industries and sectors. The emergence of smart devices, sophisticated sensors, and advanced communication protocols has given birth to a new era of connectivity. This era, often referred to as Industry 4.0, signifies a paradigm shift in manufacturing, where digital technologies are seamlessly integrated into every facet of the production process.

IoT has catalyzed this transformation by serving as the linchpin that connects physical devices with digital systems. It’s no longer just about individual devices; it’s about creating an ecosystem where devices, sensors, machines, and people collaborate in real time, exchanging information, insights, and instructions. This symbiotic relationship between the physical and digital realms redefines how industries operate, how products are manufactured, and how businesses interact with customers.

The evolution of IoT from a far-fetched concept to an integral component of Industry 4.0 underscores the relentless march of technological progress. It demonstrates humanity’s capacity to turn imagination into innovation, transcending boundaries and unlocking new possibilities. As IoT continues to evolve, it will undoubtedly shape our world, enhancing efficiency, driving innovation, and propelling us into a future where the lines between the physical and digital realms are blurred. The potential for transformative change knows no bounds.

IoT Data: The Crown Jewel of Industry 4.0

Amid the bustling world of IoT devices, sensors, and interconnected machinery, a treasure trove holds immense potential – IoT data. This data isn’t just about the sheer volume it generates; its true value lies in its capacity to illuminate the path toward unprecedented insights and data-driven decision-making. As the waves of Industry 4.0 reshape the manufacturing landscape, the judicious utilization of this data sets the stage for a new era of operational excellence and innovation.

IoT data is like a diamond in the rough, waiting to be unearthed and polished to reveal its brilliance. The data generated by countless IoT devices offers a glimpse into the intricacies of manufacturing processes, the behavior of equipment, and the performance of systems. But its significance doesn’t stop at the raw numbers; the ability to discern patterns, detect anomalies, and forecast trends truly sets this data apart.

In the modern business landscape, data isn’t just a commodity; it’s a strategic asset. Organizations invest heavily in data analytics and business intelligence to extract actionable insights from their data reserves. With its real-time nature and granularity, IoT data has positioned itself as a cornerstone of this data-driven revolution. From predicting maintenance needs and optimizing supply chains to improving quality control and enhancing customer experiences, the applications of IoT data are boundless.

Let’s put some numbers behind this phenomenon. A McKinsey report indicates that the economic impact of IoT data could be anywhere from $3.9 trillion to a staggering $11.1 trillion annually by 2025. This isn’t just a blip on the radar; it’s a seismic shift in how industries operate and how value is created. However, it’s imperative to recognize that the mere act of collecting data is just the beginning. The true transformative potential lies in our ability to harness, analyze, and translate this data into meaningful insights that drive strategic decisions.

As we stand at the precipice of a data-driven future, it’s clear that IoT data is more than just a byproduct of interconnected devices – it’s the lifeblood of Industry 4.0. The ability to extract value from this data isn’t just an option; it’s necessary for survival and growth in an era where data is the currency of progress. Let’s dive deeper into this topic.

Beyond Hype: Defining IoT Success

As mentioned above, the heart of IoT’s impact resides in how organizations manage, curate, and unleash the potential of the vast sea of data it generates. It’s not about the number of sensors or devices you deploy; it’s about how effectively you convert that data into actionable insights.

In an era where data drives decisions, the ability to harness and capitalize on IoT data is a distinguishing factor that separates thriving businesses from those merely caught up in the hype. The sheer volume of data generated by IoT devices is staggering – an avalanche of information that can transform processes, enhance customer experiences, and propel innovation. However, a strategic approach to data management is imperative to tap into this potential.

Imagine a scenario where businesses invest heavily in IoT devices and infrastructure yet struggle to derive value from the generated data. This scenario isn’t just a possibility; it’s a harsh reality for those that overlook the critical role of data management. Without an effective strategy for data collection, storage, analysis, and application, the transformative power of IoT remains locked behind a barrier of unstructured information. The journey from data collection to actionable insights is a nuanced one. It involves employing advanced analytics tools and machine learning algorithms and fostering a culture that values data-driven decision-making. Organizations that master this journey unlock the potential to enhance efficiency, optimize processes, and gain a competitive edge in the market.

Effective data management involves curating the IoT data, structuring it for analysis, and seamlessly integrating it into business processes. It’s about enabling cross-functional analytics that provide insights to not just one department but to every facet of the organization. Whether it’s optimizing production processes, enhancing supply chain efficiency, or even shaping product development, the value of IoT data transcends silos.

In this landscape, those who truly succeed are the ones who see IoT as more than a buzzword – they see it as a strategic imperative. They recognize that if they can’t curate their IoT data and leverage it for business intelligence and cross-functional analytics, their investment in IoT becomes nothing more than a fad. To ensure IoT success, businesses must cultivate a culture that champions data-driven decision-making. It fosters collaboration between data scientists, engineers, analysts, and business leaders to extract insights that fuel innovation and growth. This requires not just technology but a mindset shift that places data at the heart of strategic planning and execution.

The need for effective IoT data management will only intensify as the digital landscape evolves. The businesses that understand this reality that unlock the potential of their IoT data through meticulous curation and strategic application are the ones that will shape the future of Industry 4.0. So, while IoT devices and sensors form the foundation, the data they generate constructs the edifice of success.

Real-Life Examples of Manufacturing Companies Leveraging IoT Data

Here are some examples of manufacturing companies that are effectively leveraging their IoT data to drive innovation, efficiency, and improved operations:

- Siemens AG: Siemens, a global powerhouse in industrial manufacturing, uses IoT data to enhance its industrial automation solutions. Through its Industrial Internet of Things (IIoT) platform, MindSphere, Siemens enables customers to connect their machines, analyze data, and gain insights to optimize processes, reduce downtime, and increase productivity. For instance, MindSphere allows predictive maintenance by analyzing sensor data from machinery, enabling timely interventions to prevent breakdowns.

- General Electric (GE): GE has embraced IoT-driven innovation in various sectors, including aviation and healthcare. In aviation, GE’s IoT-powered jet engines collect vast amounts of data during flight, which is then analyzed to improve fuel efficiency, optimize maintenance schedules, and enhance safety. Similarly, in healthcare, GE’s IoT solutions enable medical devices and equipment monitoring, ensuring they operate reliably and efficiently.

- Ford Motor Company: Ford utilizes IoT data to enhance its manufacturing processes and improve vehicle performance. The company collects data from sensors embedded in its assembly line machinery and vehicles. This data is analyzed to optimize production efficiency, identify potential quality issues, and enable real-time adjustments to manufacturing operations.

- Procter & Gamble (P&G): P&G, a consumer goods giant, employs IoT data to optimize its supply chain and enhance product quality. The company utilizes IoT sensors in its production lines to monitor temperature, humidity, and pressure. This data helps P&G ensure consistency in product quality, reduce waste, and respond quickly to any deviations in manufacturing processes.

- Airbus: Airbus, a leading aircraft manufacturer, harnesses IoT data to improve aircraft maintenance and operation. The company’s “Airbus Skywise” platform aggregates data from its aircraft fleet and analyzes it to identify trends and anomalies. This proactive approach allows Airbus to predict maintenance needs, optimize flight operations, and enhance safety by addressing potential issues before they escalate.

These examples highlight how diverse manufacturing industries are leveraging IoT data to drive efficiency, innovation, and customer value. From automakers to consumer goods manufacturers and aerospace companies, IoT data is proving to be a game-changer in transforming traditional manufacturing practices.

Microsoft Azure: Pioneering IoT Adoption

In IoT, where data reigns supreme, having a robust and versatile platform to manage and utilize this data becomes paramount. Microsoft Azure emerges as a trailblazer, playing a pivotal role in shaping the adoption and success of IoT in the manufacturing sector. As organizations navigate the complexities of IoT data management, Azure offers a comprehensive suite of solutions that pave the way for innovation and efficiency. At its core, Microsoft Azure recognizes that IoT is not just about devices and sensors; it’s about transforming data into insights that drive action.

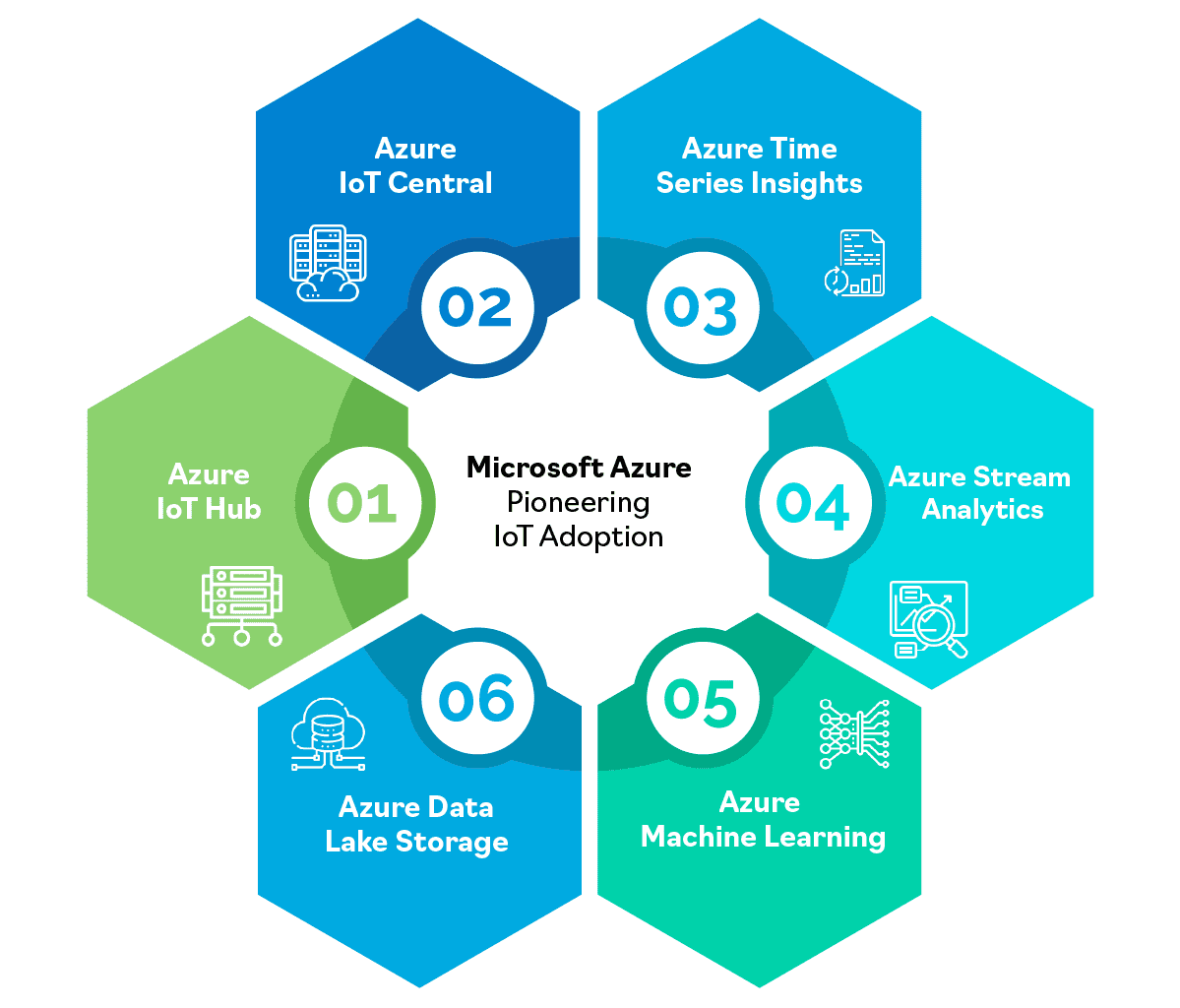

Microsoft Azure offers a range of tools and services specifically designed to help manufacturing companies leverage their IoT data effectively. These tools enable organizations to seamlessly connect, manage, and derive insights from their IoT devices, ultimately driving operational excellence and innovation. Here are some of the key tools provided by Microsoft Azure for leveraging IoT data in the manufacturing sector:

- Azure IoT Hub: Azure IoT Hub is a fully managed service that serves as the central nervous system for IoT solutions. It allows bi-directional communication between IoT applications and the devices it manages. IoT Hub enables secure and reliable data communication between devices and the cloud with features like device-to-cloud telemetry, cloud-to-device messaging, and device management capabilities. Manufacturers can monitor, manage, and update their IoT devices remotely, ensuring seamless operations and real-time insights.

- Azure IoT Central: Azure IoT Central is a platform-as-a-service solution that simplifies the creation and deployment of IoT applications. It provides pre-configured templates for various industries, including manufacturing. This enables manufacturers to quickly build and deploy IoT solutions without extensive coding or development efforts. Azure IoT Central empowers organizations to monitor their IoT devices, collect data, and visualize insights through customizable dashboards.

- Azure Time Series Insights: This tool allows manufacturers to explore and analyze time-series data from IoT devices at scale. Azure Time Series Insights provides a platform for storing, querying, and visualizing time-stamped data, helping organizations identify patterns, trends, and anomalies in their IoT data. It offers interactive analytics capabilities that enable users to gain deeper insights into historical and real-time data.

- Azure Stream Analytics: For manufacturers seeking real-time insights from their IoT data streams, Azure Stream Analytics is a valuable tool. It enables organizations to process and analyze streaming data from IoT devices in real time, providing the ability to trigger immediate actions based on the data’s insights. This tool is particularly useful for applications like predictive maintenance and real-time monitoring.

- Azure Machine Learning: While not exclusive to IoT, Azure Machine Learning empowers manufacturers to build, deploy, and manage machine learning models that can leverage their IoT data. With the ability to create predictive models, anomaly detection algorithms, and other AI-driven solutions, Azure Machine Learning enhances decision-making by harnessing the value hidden within the IoT data.

- Azure Data Lake Storage: Effective data management is critical in IoT scenarios, and Azure Data Lake Storage provides a scalable and secure repository for storing vast amounts of IoT data. It accommodates structured and unstructured data, facilitating easy data ingestion, storage, and retrieval for analysis and reporting purposes.

These tools collectively provide manufacturers with a comprehensive ecosystem to capitalize on their IoT data. From data collection and storage to real-time analytics and machine learning, Microsoft Azure’s offerings equip businesses with the means to transform raw data into actionable insights, leading to improved operational efficiency, informed decision-making, and a competitive edge in the dynamic landscape of modern manufacturing.

The Data Dynamics Advantage

In collaboration with Data Dynamics, Microsoft has introduced the Azure File Migration Program, a revolutionary offering that aligns seamlessly with manufacturing companies’ aspirations to leverage their IoT data effectively. This partnership empowers enterprises to migrate their data to Azure effortlessly and energizes intelligent data management across On-Premise, Azure, and Hybrid Cloud environments, thus enhancing operational efficiency.

By joining this program, manufacturing organizations gain the tools to seamlessly transition their data to Azure, ensuring the integrity and security of their IoT data. This collaboration addresses critical challenges manufacturers face in their journey towards IoT-driven transformation, enabling them to navigate complexities and fully harness the potential of cloud computing.

The Azure File Migration Program, powered by Data Dynamics, addresses the critical challenges encountered during the cloud migration journey. It tackles issues like cost, speed, talent, and risk, helping organizations navigate the complexities and unlock the full potential of cloud computing.

To learn more about Data Dynamics and how our platform can help you achieve seamless data migration, efficient data management, and cost optimization within Azure, visit our website at www.datadynamicsinc.com/microsoft/. You can also contact us at solutions@datdyn.com or (713)-491-4298 or +44-(20)-45520800. Let us be your trusted partner in cloud migration and data management.