For centuries, the manufacturing sector has played a pivotal role in driving global economic growth. But now, with the emergence of Industry 4.0, this field is undergoing a significant overhaul – and data is at the heart of it all. Mind-bogglingly, the average manufacturing enterprise generates a whopping 1 TB of production data every day. Yet, shockingly, only a mere 1% of that data is ever analyzed and utilized in real-time. To stay ahead of the curve, companies must find an efficient way to manage & analyze their data cohesively and use it to gain valuable, actionable insights for making informed decisions. This is where data fabric comes into play – a revolutionary concept that allows businesses to seamlessly integrate disparate sources of information and derive meaningful value from it. In this blog post, we’ll explore how implementing data fabric can benefit the manufacturing industry, revolutionizing how organizations approach data management. So sit tight as we delve deep into this exciting topic!

What is data fabric? How is it being used in various sectors?

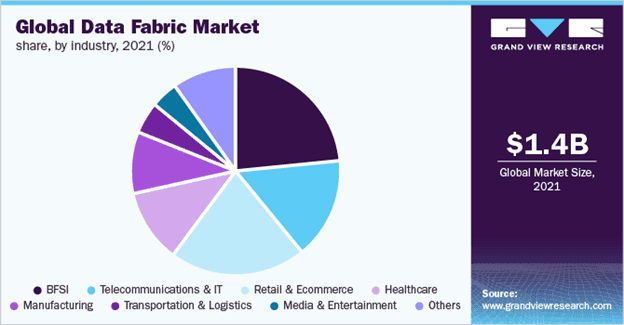

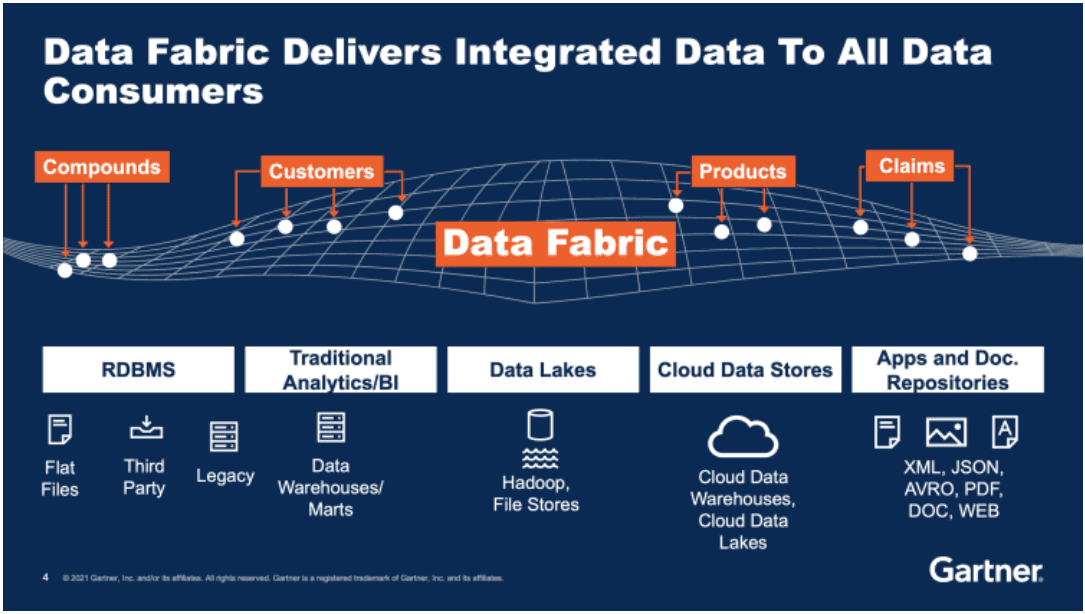

Data fabric is a term used to describe a unified data management system that enables businesses to manage their data across multiple clouds, applications, and systems. It ensures that all the data is consistent, accurate, and accessible in real time. The concept of data fabric is being increasingly adopted by various sectors due to its ability to provide seamless integration of different types of data from disparate sources. By providing a single view of the entire dataset, it becomes easier for organizations to gain insights into their operations and make better decisions based on those insights.

In healthcare, data fabric can integrate patient records from multiple providers or hospitals into one comprehensive record. This makes it easier for doctors and medical professionals to access patient information quickly and accurately. Similarly, in finance, enterprises can use the data fabric technology to aggregate customer transactional histories across multiple channels such as ATM transactions, mobile banking apps or online banking portals, allowing banks or other financial institutes with more detailed analytics of user activities leading towards improved decision-making processes.

The concept of implementing Data Fabric revolves around achieving optimal business efficiency by adopting a centralized approach to manage operational intelligence. This approach not only streamlines processes but also leads to cost savings and heightened productivity. In essence, Data Fabric empowers organizations to harness their data resources effectively, resulting in improved operational outcomes and increased overall performance.

Data Fabric in Manufacturing

In the world of manufacturing, data is king. And with the rise of Industry 4.0, there’s no better time for companies to invest in cutting-edge technology that can help them gain valuable insights from their data. Enter Data Fabric – the game-changing solution that’s revolutionizing the manufacturing sector.

Manufacturers are turning to Data Fabric to streamline their operations and gain real-time insights from their disparate data sources. This innovative technology provides a unified view of enterprise data, enabling manufacturers to make informed decisions quickly and efficiently. The benefits of implementing a robust data fabric solution are endless – from optimizing supply chain logistics to improving overall product quality.

But that’s not all. With real-time access to critical business metrics, data fabric is empowering manufacturers with unprecedented insight into their businesses’ health at all times. This allows them to utilize advance analytics tools to monitor production processes and ensure quick reaction time when needed most – whether that’s identifying bottlenecks and inefficiencies in real-time, predicting equipment failures before they occur, optimizing supply chain logistics, and improving overall product quality. Additionally, as cloud-based deployments are becoming more prevalent in the industry, Data Fabric technology can be leveraged to achieve hybrid-cloud architectures that reduce IT overheads while scaling up infrastructure as per business needs.

Reducing costs is another significant benefit of implementing a data fabric in manufacturing. By analyzing operational data, companies can identify opportunities for cost savings without sacrificing quality or efficiency. This enables them to optimize their processes while ensuring optimal product quality and reducing costs – ultimately leading to greater success.

In a fiercely competitive landscape, implementing Data Fabric into manufacturing environments is a no-brainer for organizations looking to stay ahead. It offers endless possibilities for improved efficiency and productivity, making it a crucial consideration for manufacturers seeking to thrive in the current business climate.

Here are some examples of manufacturing companies that joined the Data Fabric revolution and took their manufacturing operations to the next level!:

- Siemens: Siemens is a global manufacturing company that produces a wide range of products, including industrial automation systems, power generators, and medical equipment. Siemens implemented a data fabric to collect data from its manufacturing operations and use it to optimize its production processes. The result – Siemens was able to integrate data from multiple sources, including machines, sensors, and databases, to comprehensively view its operations. By leveraging the data fabric, Siemens identified and addressed inefficiencies in its manufacturing processes, resulting in increased productivity and reduced costs.

- BMW: BMW is a leading manufacturer of luxury vehicles, with operations in over 150 countries. BMW implemented a data fabric to collect data from its production facilities, supply chain management systems, and customer feedback channels. The result – BMW successfully analyzed data in real-time, quickly identifying and addressing quality issues. By leveraging the data fabric, BMW improved the quality of its vehicles, resulting in increased customer satisfaction and improved brand reputation.

- Ford: Ford is one of the world’s largest automobile manufacturers, producing a wide range of vehicles, including cars, trucks, and SUVs. Ford implemented a data fabric to collect data from its production facilities and supply chain management systems. The result – Ford could optimize its manufacturing processes, reducing downtime and improving productivity. By leveraging the data fabric, Ford improved the efficiency of its production facilities, resulting in reduced costs and increased profitability.

Impressive, isn’t it? With all the benefits that Data Fabric technology can bring, it’s surprising that not all manufacturers have implemented it yet. So, what’s stopping them? Ironically, the answer lies in data itself. Let’s take a closer look at the root cause of this problem and explore potential solutions.

The Biggest Roadblock to Data Fabric – Unstructured Data

In 2012, General Electric discovered that one of its factories had the capacity to produce 5,000 data samples every 33 milliseconds, while a single product line alone could generate up to 4 trillion data points per year – and this was over a decade ago. Today, with the emergence of Industry 4.0, the amount of data being generated is staggering. Unlike traditional factories that only produce physical goods, smart factories create both products and data, which must work in tandem to achieve enhanced productivity and efficiency. For instance, the performance logs of a single works machine can generate approximately 5 gigabytes of data every week, and a typical smart factory can produce as much as 5 petabytes per week – that’s the equivalent of over 300,000 16 GB iPhones!

However, the excitement of this data revolution is tempered by the fact that over 80% of this data is unstructured, presenting a significant challenge for manufacturers.

Unstructured data is the kind of information that doesn’t fit neatly into a database or spreadsheet. It might come from visual inspections, rather than numerical measurements, or be generated by a variety of sources throughout the organization. The result is what experts call “data sprawl,” where valuable information becomes scattered and difficult to access.

For manufacturers, this creates a major roadblock to implementing a data fabric – a unified system for managing and analyzing data to optimize processes. Without proper management, unstructured data can grow exponentially over time, limiting the effectiveness of a data fabric. In other words, manufacturers risk missing out on valuable insights that could help them make better decisions and optimize their processes. Often, unstructured data is “siloed” or isolated by division, separating it from the rest of the company. It is estimated that more than two thirds of manufacturing data goes unused.

But there is hope. By focusing on data management techniques like metadata analysis, context and content analytics, manufacturers can structure their unstructured datasets into usable formats to gain a deeper understanding of their processes and uncover insights that were previously hidden. This, in turn, allows them to optimize their operations, improve product quality, and reduce costs. So, while unstructured data presents a significant obstacle to implementing a data fabric in the manufacturing industry, it can be efficiently managed to maximize the return on investment (ROI) derived from this technology. Let’s explore how.

Taming the Unstructured: How Unified Data Management Can Help You Make Sense of Dark Data

As mentioned above, the main hurdle when dealing with unstructured data is the difficulty in analyzing and extracting valuable insights from it. However, an effective solution to this challenge is to implement unified data management.

Unified Data Management Platform (UDMP) is a technology solution that integrates multiple data management functionalities, such as data integration, data warehousing, data governance, data quality, and data security, into a single platform. This approach helps to minimize the sprawl of dark or unused data in various silos across the organization and protects sensitive data at risk.

By consolidating all relevant information in a centralized location such as a “Data Fabric,” manufacturers can obtain more profound insights into their operations, secure their data and optimize their storage infrastructure spread across multiple datasets stored in multiple locations. The use of unified data management tools to optimize the value of Data Fabric technology results in better decision-making and decluttering of datasets, leading to significant cost savings for manufacturing organizations.

To implement a data fabric successfully in the manufacturing sector, companies need to focus on three techniques that can help manage unstructured data effectively. These techniques are metadata analytics, and context analytics.

- Metadata is information about the data that helps describe its content and structure. By using metadata, manufacturers can organize their unstructured data more efficiently. Metadata tags can include details such as date of creation, author name, or origin location, making it easier for businesses to find relevant information quickly, archive and tier their data based on usage (hot vs cold). Additionally, by categorizing, tagging and eliminating redundant, obsolete and trivial data (ROT), metadata analytics help enterprises reduce their data sprawls.

- Content analytics is another technique that helps analyze unstructured data by identifying patterns within text documents or other types of digital media like images and videos. This process involves extracting insights from large volumes of text-based content by categorizing it into different topics based on keywords or phrases used in those documents. Content analysis is best used for identifying sensitive data and taking the required steps to remediate it – quarantine, access control and audit.

- On the other hand, context analytics focuses on understanding how different pieces of unstructured data relate and how they fit into broader business goals. It considers factors such as user behavior patterns when accessing certain types of files, which enables businesses to make better decisions based on a holistic view rather than just individual pieces of information. With this, businesses can gain valuable insights from their structured and unstructured datasets while reducing costs for storing large amounts of dark (uncategorized)data.

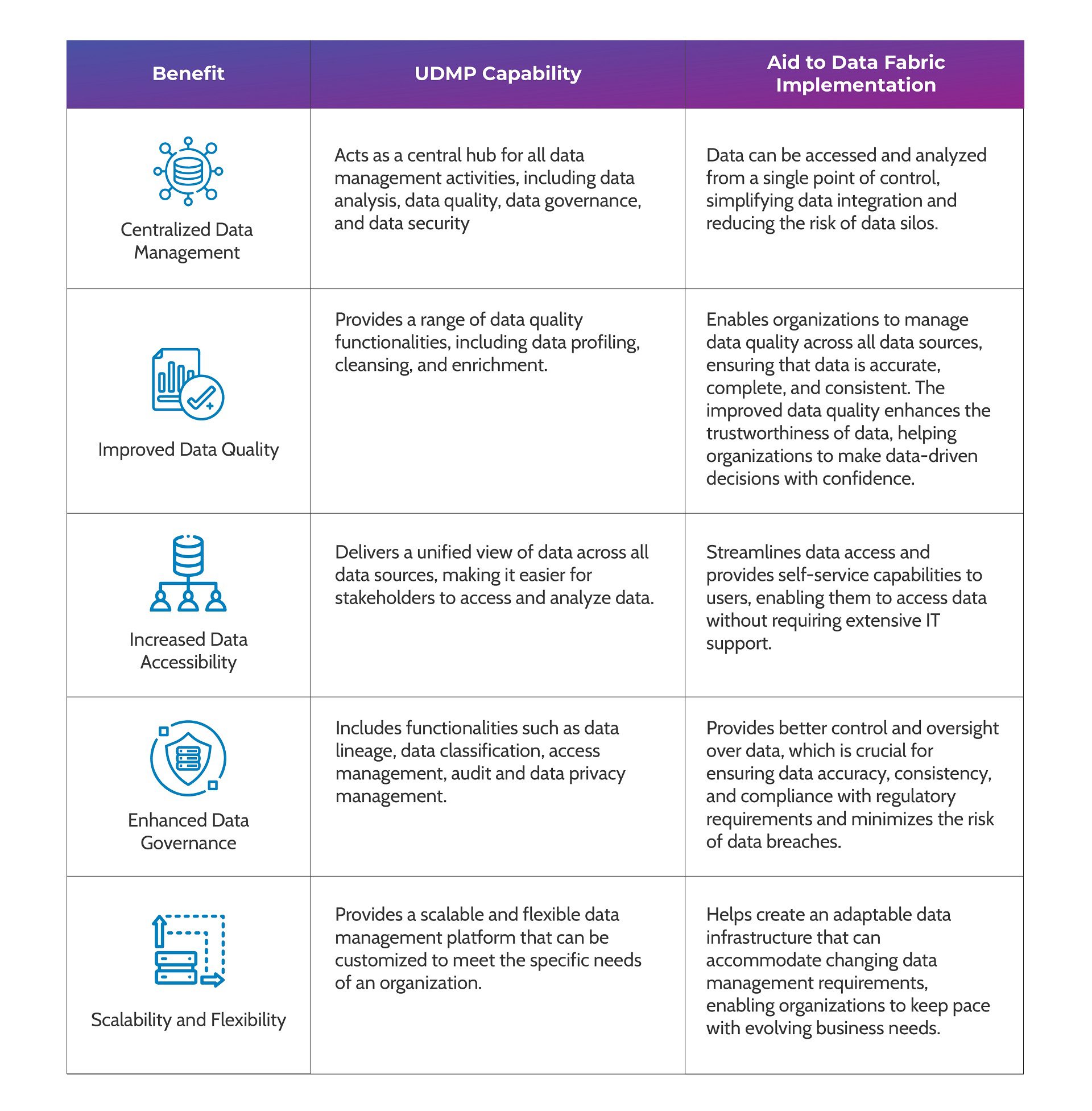

5 ways how Unified Data Management Platform aids Data Fabric Implementation

The primary objective of a UDMP is to simplify data management, reduce data silos, and enhance the availability and accessibility of data for various stakeholders. When integrated with a Data Fabric architecture, UDMP can significantly improve data management capabilities and increase the efficiency and effectiveness of data-driven decision-making. Here’s how

The Data Dynamics Advantage

As the world hurtles towards Industry 4.0, the manufacturing landscape is rapidly evolving, with smart factories generating an unprecedented amount of data every day. To stay competitive in this rapidly evolving industry, manufacturers need to adopt innovative technologies such as a combination of Data Fabric and Unified Data Management.

Enter Data Dynamics – the game-changing provider of enterprise data management solutions.

With their Unified Unstructured Data Management Platform, Data Dynamics is leading the charge in helping organizations harness the power of unstructured data. This revolutionary platform comprises four modules – Data Analytics, Mobility, Security, and Compliance – and has already been proven successful in over 300 organizations, including 28 Fortune 100 and 5 Fortune 500 manufacturing enterprises.

The Data Dynamics platform is the ultimate one-stop solution that empowers manufacturers to fully leverage unstructured data and gain a competitive edge in the market by using technologies like Data Fabric. The platform enables organizations to easily categorize, tag, index, analyze, archive and migrate data across multiple sources, providing a structured and refined view of the data that transforms it from mere storage to valuable business assets.

With Data Dynamics, manufacturers can identify the most useful types of data and determine where and how to store it, thereby reducing data sprawl, consolidating data lakes and centers, and optimizing storage. This makes it easier than ever for companies to implement a Data Fabric model, thereby setting themselves apart in the competitive manufacturing landscape.

To learn more about how Data Dynamics can help your enterprise stay ahead of the curve and unlock the full potential of your data, please visit – www.datadynamicsinc.com or contact us at solutions@datdyn.com I (713)-491-4298.